A. Hatzopoulos S.A. & ROVEMA bei der Warschau Pack 2024.

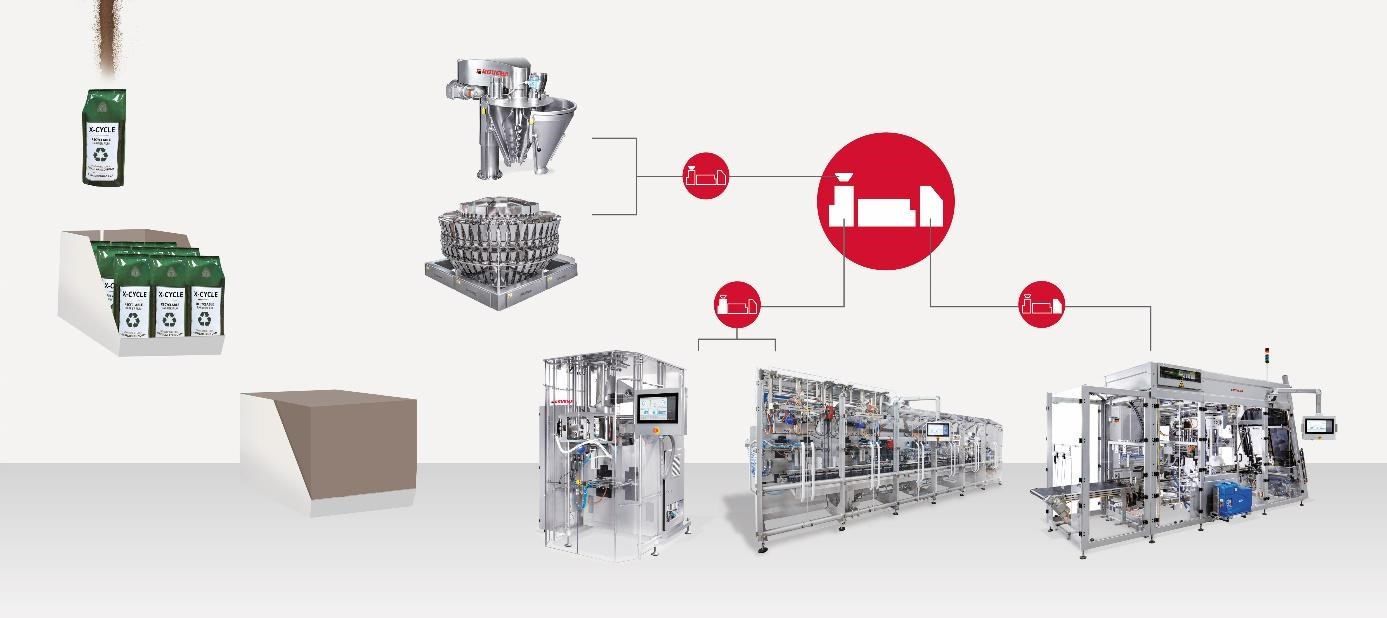

Vom 23. bis 25. April, während der Messe Warschau Pack 2024 in Polen, waren unsere X-CYCLE™ PP-Materialien am ROVEMA-Stand live im Einsatz. Die innovative Monomateriallösung für Kaffeeverpackungen, die wir für diese Veranstaltung in Zusammenarbeit mit ROVEMA entwickelt haben, bietet Nachhaltigkeit, hohen Schutz und volle Funktion bei einer Ausstoßleistung von 70 stabilen, vollständig recycelbaren Seitenfalten-Kaffeepackungen mit Aromaventil pro Minute, die mit der auf der Messe ausgestellten BVC 260-Linie erreicht werden.

![]()

Adresse

Ptak Warsaw Expo Al. Katowicka 62 05-830 Nadarzyn, Poland

Hall 5 | Stand F5.19

![]()

Datum

Dienstag, April 23: 10:00am-5:00pm

Mittwoch, April 24: 10:00am-5:00pm

Donnerstag, April 25: 10:00am-5:00pm

About ROVEMA:

With passion and the experience of more than 60 years, ROVEMA develops and builds packaging machines and lines that meet the complex demands of the modern circular economy. ROVEMA thinks holistically and considers the environment, the market, the product and the packaging in projects from the very beginning. This enables the development of efficient and sustainable packaging machines with high availability. A sustainable solution that fits the characteristics of the product to be packaged and its requirements for logistics, packaging material, shelf life and energy efficiency is ROVEMA’s top priority. A successful concept – ROVEMA has already delivered more than 30,000 machines and lines worldwide.

At the Warsaw Pack trade show ROVEMA is exhibiting a BVC 260 of continuous operation specifically for packing coffee – ground coffee, coffee beans, agglomerated or freeze-dried coffee can be processed with gentle product handling and accurate weight. For coffee applications requiring a degassing valve, the machine is equipped with the particularly high-performance new ROVEMA valve applicator for button valves. Packing materials from the flat film web are used, and the aroma valve is fitted in the reel carrier of the packaging machine, offering maximum flexibility at this point as well: the process allows an even wider sealing window, which can be adapted to the requirements of the particular packing material and the button valve selected.